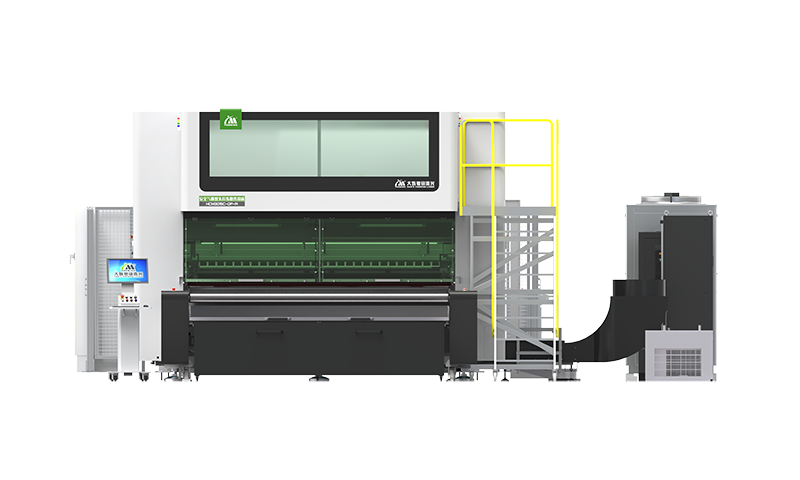

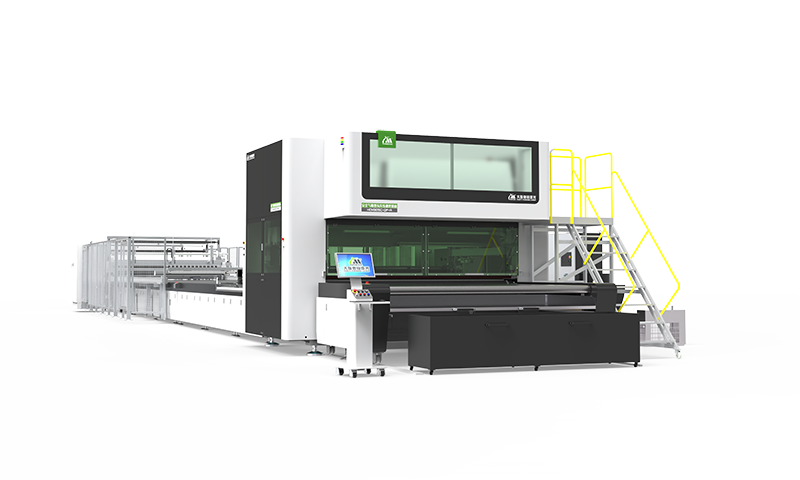

Model

Dual-Head Asynchronous Laser Cutting Bed System for Airbags

Introduction

Adopt linear motor to the transmission system, getting max acceleration up to 4G.max speed up to 150m/min;

Asynchronous double cutting heads, Fly Cutting, and Intelligent task arrangement,maximize the processing efficiency;

Stepless speed adjustment of the exhaust fan enables the intelligent adjustment on the value of negative exhausting pressure in cutting area according to different situations;

Inquiry

.jpg)

.jpg)

.jpg)

.jpg)