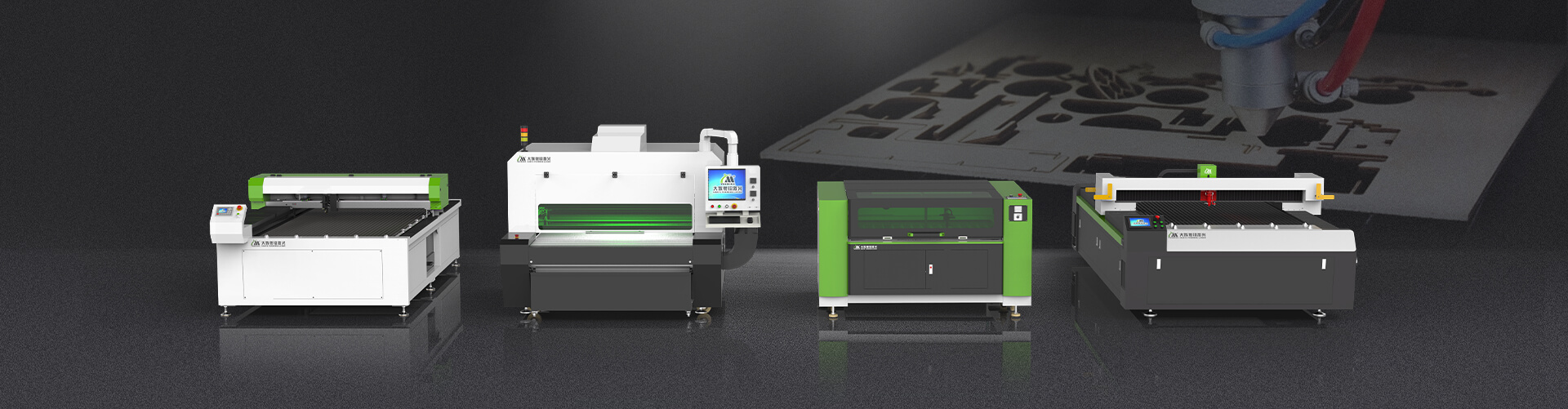

Model

High-power Airbag Laser Cutting Machine CMA2425C-GF-C

Introduction

RofinDC series high power CO₂ laser generator, stable performance, high density light spot, low maintenance cost and long service life; The unloading unit and the cutting unit are designed separately to keep the working efficiency of the unloading and cutting synchronization; Distributed abstracting air structure, effectively absorbing and cutting dust particles, to realize clean and environmental cutting; The whole machine adopts CNC automatic lubrication system to keep 24 hours continuous cutting.

Inquiry