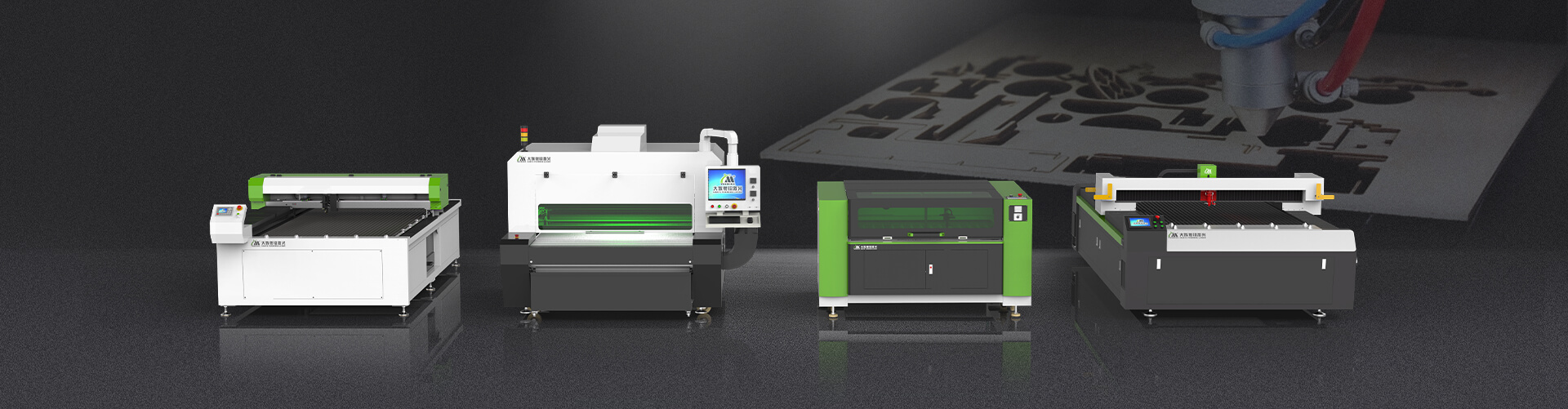

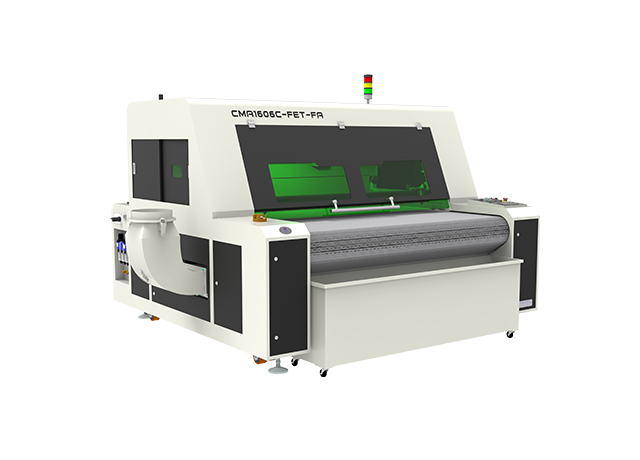

Model

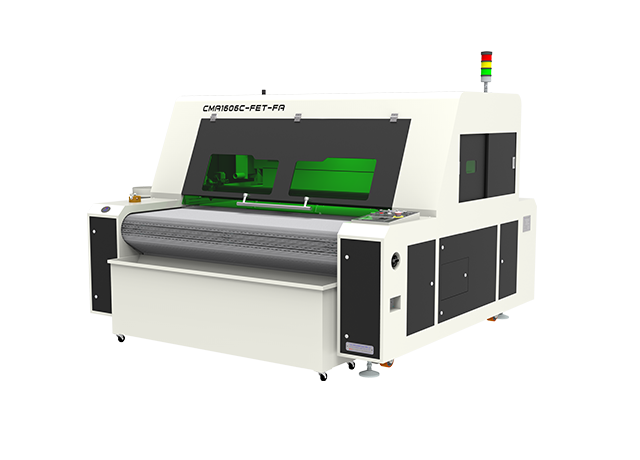

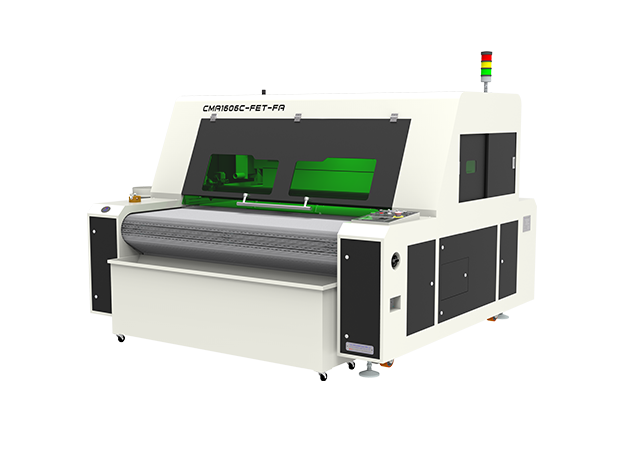

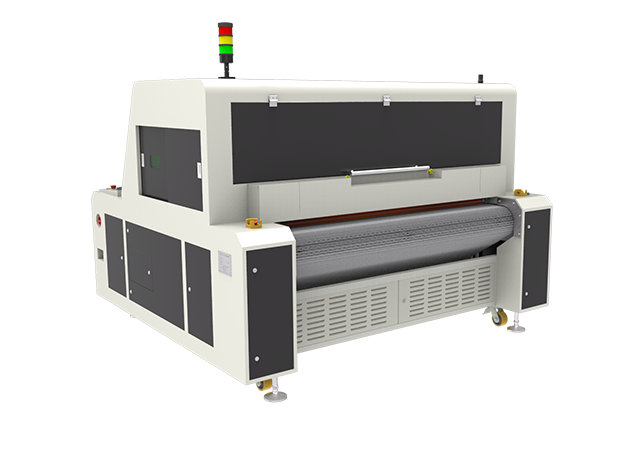

Double Heads Auto Feeding Laser Cutting Machine Series CMA1606C-FET-FA

Introduction

Comply with CE certification safety standards, effectively protecting the safety of operators. Automatic generation of machining trajectories for offline simulation of machining. Automatically check and solve collision and singularity problems, etc. Without operating multiple software, accuracy and stability of equipment operation are higher. Precise cutting, high speed cutting according to the contour line after match. Auto-nesting software,support pair nesting,single side nesting,mixed nesting and scrap material nesting. Large format vision positioning,fast scan shot for the whole working area, contour line extraction and match well.

Inquiry