Model

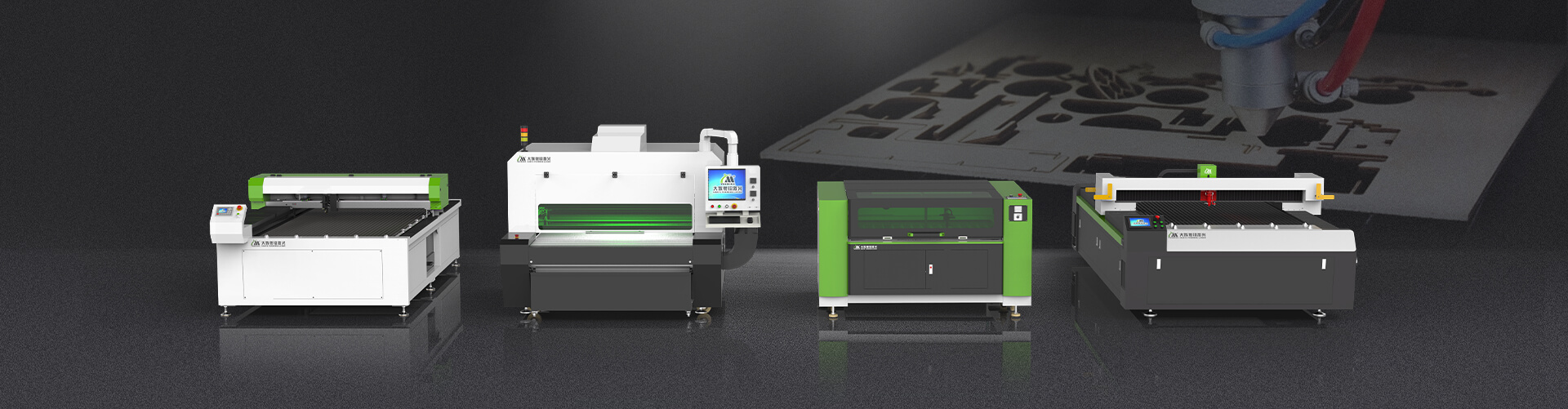

Textile Fabric Laser Cutting Machine Series CMA1825C-DF-B

Introduction

Reinforced welding body processed by the large gantry precision milling. Heat treatment technigne such as tempering, vibration aging adopted on key parts to ensure machine long term stability and accuracy; Dual-beam asynchronous laser cutting system: two laser heads working separately, achieve optimal cutting path allocation, effectively improving work effificiency and saving materials; Synchronized rack & pinion system, max positioning speed 60m/min; High rigidity enhanced aviation aluminum gantry, improve the gantry strength and rigidity and much lighter; Automatic lubrication: the lubrication time period can be set in the software, to ensure the accuracy of transmission system; It is suitable for majority of fabrics materials.

Inquiry