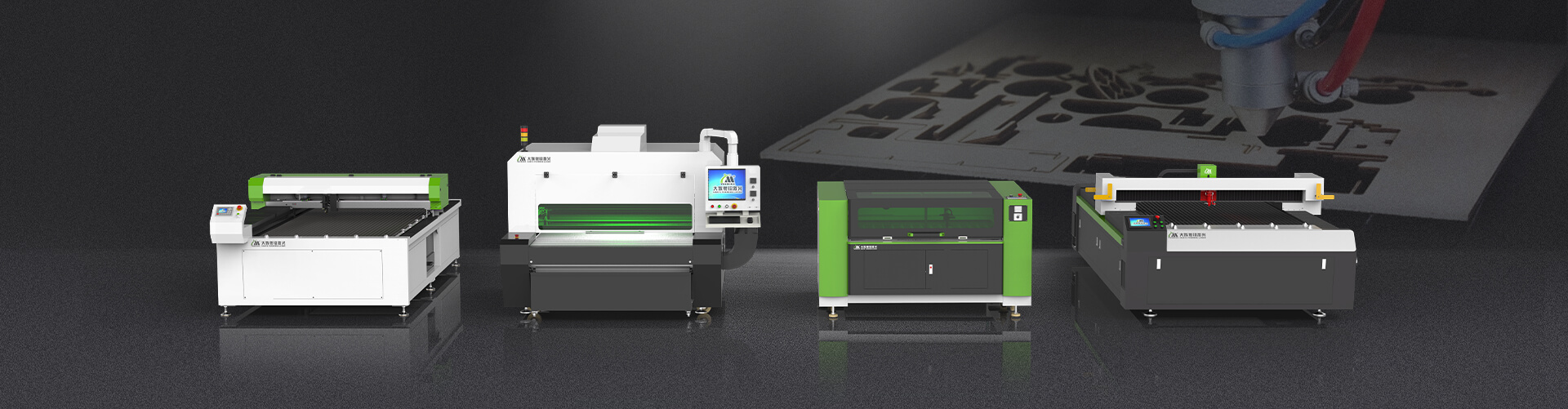

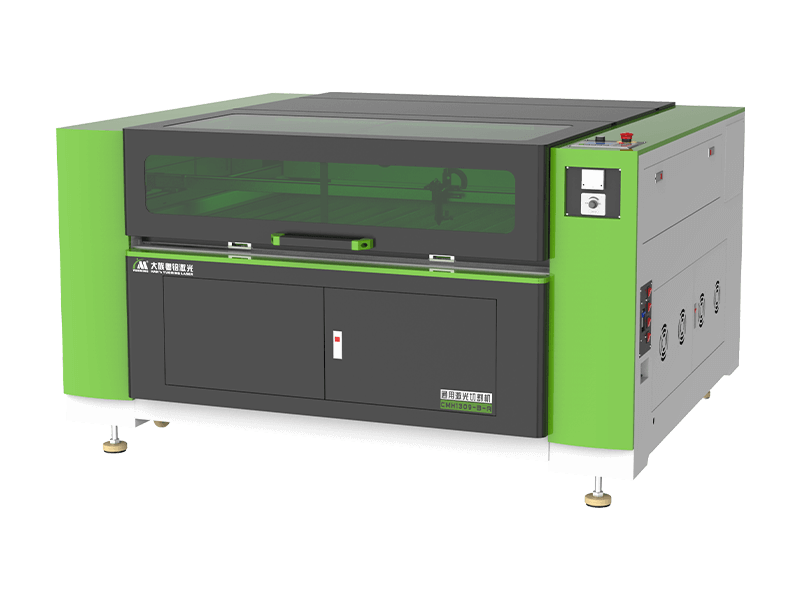

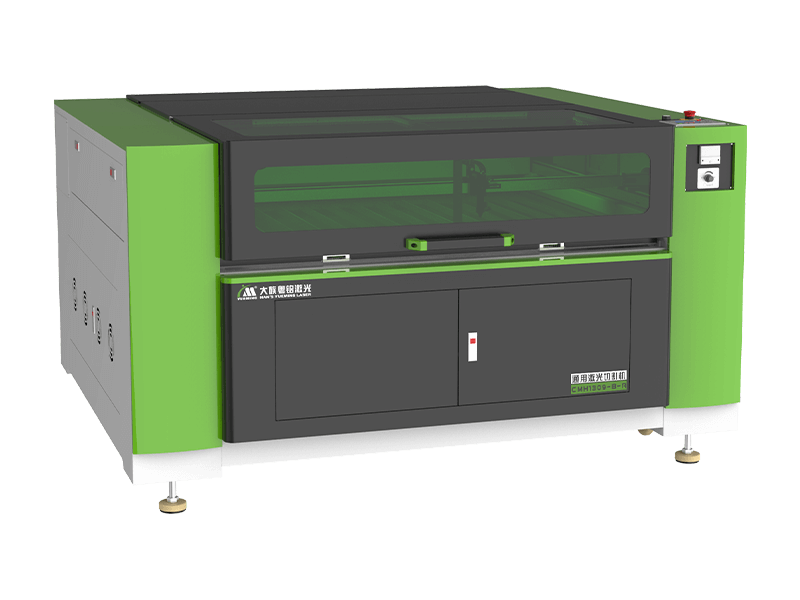

Model

CO2 Laser Cutting Machine Series CMH1309-B-A

Introduction

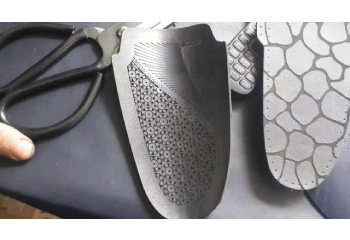

CO2 laser cutting machine series, cutting and engraving combined in one machine, for non-metal material, 1mm–30mm thickness cutting ability, widely used for acrylic, plywood, leather, fabric, plastic, rubber and bamboo, etc.

Working area: 600*400mm, 1000*800mm, 1200*600mm, 1300*900mm, 1600*1000mm, 1600*1200mm