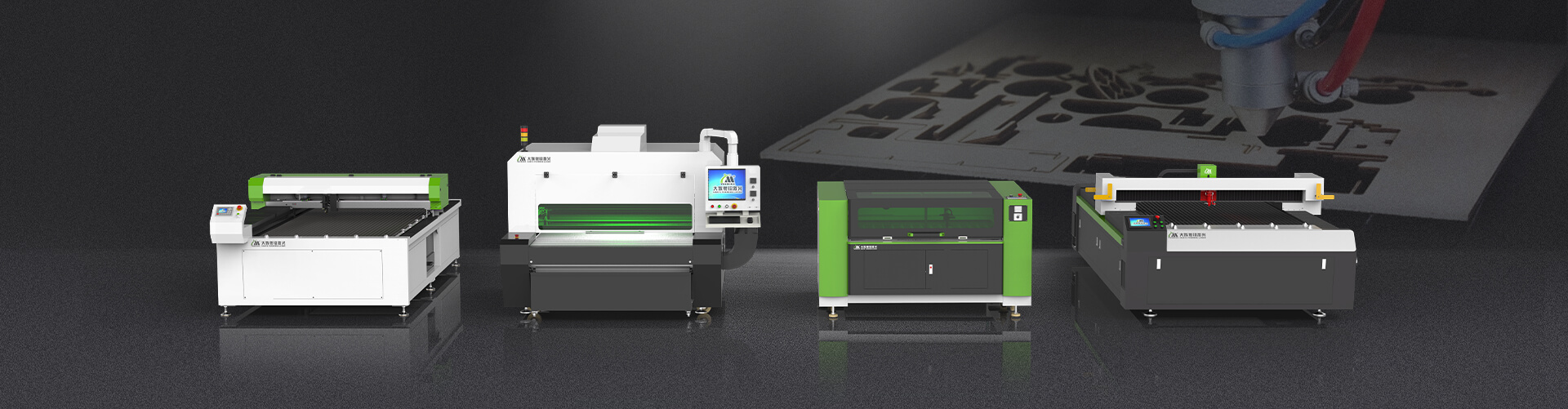

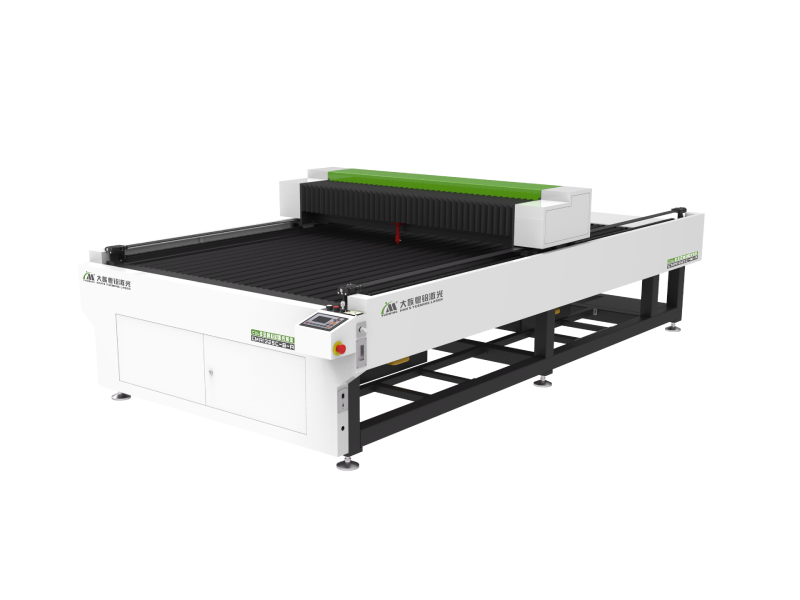

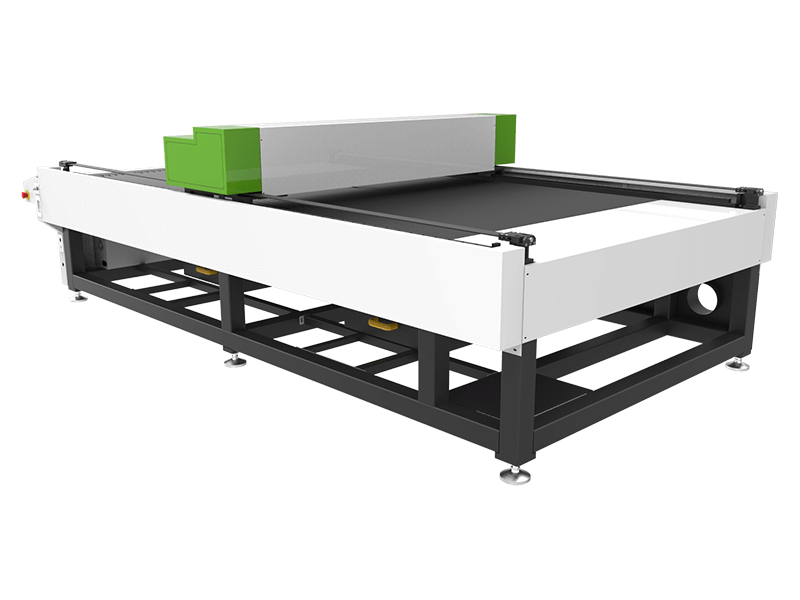

Model

Non-metal Plate Laser Cutting Machine Series CMA1325C-B-A

Introduction

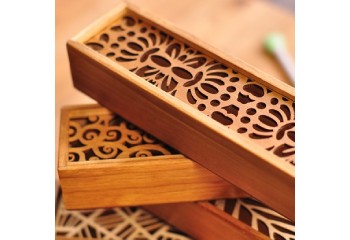

Non-metal plate laser cutting machine series with working area 1300*2500mm designed mainly for signage industry , acrylic, plywood, MDF material cutting, different configuration version meet customer requirement

Inquiry