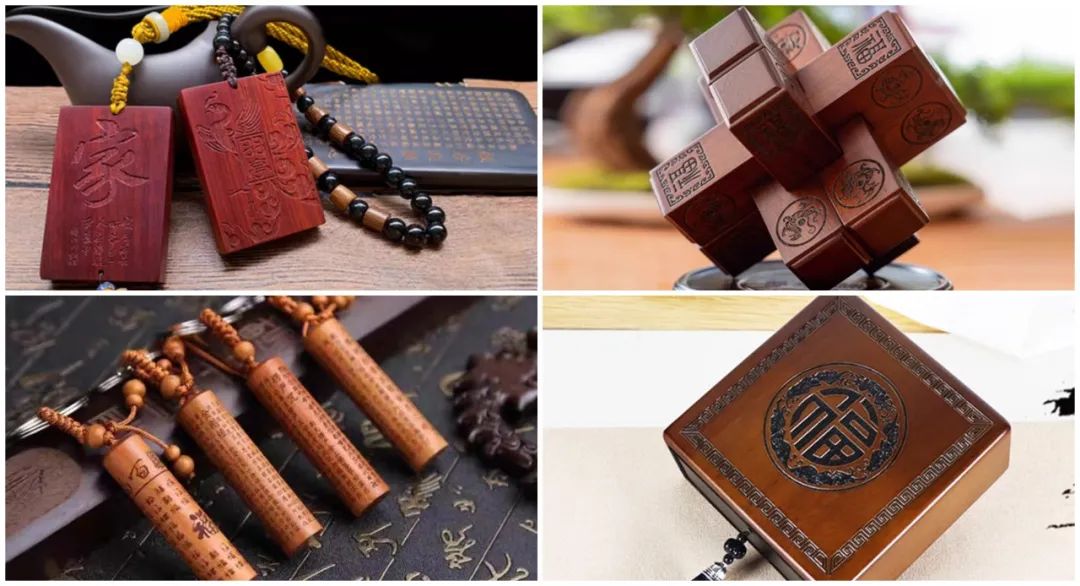

Wood products, with its natural texture and malleability, have always held an irreplaceable position in the gift industry throughout history. Amid the wave of consumption upgrades, laser engraving technology delivers high precision, superior quality, and intelligent adaptability. These capabilities are empowering wood products with entirely new artistic value, transforming an ordinary piece of wooden board in moments into a high-end work of art full of visual appeal and market value.

Advantages analysis of laser engraving on wooden boards

The intelligent, automated, and flexible processing methods of laser engraving equipment break free from the constraints of traditional cutting tools and manual labor. It utilizes computer-aided design and layout, making it suitable for the design and innovation of various complex patterns. The laser equipment can not only effortlessly cut flat graphics but also process complex, multi-layered 3D patterns. The processed edges are smooth and precise, with fluid lines that convey a high-end texture.

Compared with traditional hand carving or etching methods, laser engraving on wood offers the following key advantages:

Ultimate precision, instantly exuding a premium feel

The laser engraving accuracy can reach 0.01mm, which can easily realize various complex patterns, tiny texts, and ultra-fine gradient effects, presenting a high-end sense of great artistic value. This level of detail enhancement is difficult to achieve with traditional handcrafting or mechanical engraving.

Non-contact processing that preserves the substrate

Laser engraving is a non-contact process that does not generate physical pressure, preventing cracks, deformation, or other damage to the wooden board during engraving. The yield rate is extremely high, making it particularly suitable for precise engraving on thin wood boards and precious woods such as rosewood and black walnut.

High efficiency, enabling large-scale productivity

Compared with traditional manual methods, laser engraving can achieve efficiency at the level of minutes or even seconds, making it widely suitable for diversified and customized processing, with a significant advantage in batch production.

Intelligent operation reduces labor costs

The laser engraving machine is equipped with a professional intelligent system that automatically arranges layouts and optimizes processing paths, eliminating the need for manual drawing, templates, or any auxiliary patterns. The operation is simple and intelligent, easy to learn and master, greatly reducing reliance on skilled workers and lowering labor costs for customer enterprises.

Wide application and diverse functions

Laser engraving is suitable for a variety of woods, including black walnut, basswood, peach wood, rosewood, bamboo, and red sandalwood. It can easily perform surface, relief, and deep engraving on both flat and curved surfaces, meeting diverse processing requirements.

Laser engraving equipment recommendations

Laser engraving offers ultra-precise processing at the micrometer level, effortlessly creating intricate patterns and delicate lines. Whether it is a retro totem, meticulous painting, modern precision design, or emotional portraits, lifelike landscapes or animals, they can all be presented instantly and accurately, making each work a unique art carrier. It is widely applicable in home decoration, high-end gifts, cultural and creative products, and advertising displays. It preserves the natural texture of wood while enabling precise artistic expression through technology, with its market potential rapidly growing.

CMH0906 High Speed Laser Engraving Machine

It supports stable engraving at speeds up to 1.2 meters per second and can start and stop rapidly under 1.5 times gravitational acceleration, achieving extremely high processing efficiency.

Equipped with the self-developed SmartCarve5 software platform and uCut controller, it supports computer-aided design (CAD), graphic processing, and other functions.

It features a built-in local process library, allowing process data to be uploaded and downloaded at any time, and can be directly accessed when needed.

Equipped with a belt, hybrid servo motor, and self-developed internal rail transmission, it offers fast response and more precise control.

The fine laser spot delivers delicate and smooth engraving results, with clear and three-dimensional contours, creating a more premium look.

The machine features an integrated design with no external auxiliary units, compact in size and space-saving.

It supports various processing techniques such as deep engraving, relief engraving, hole drilling, rotary engraving, and thin sheet cutting.