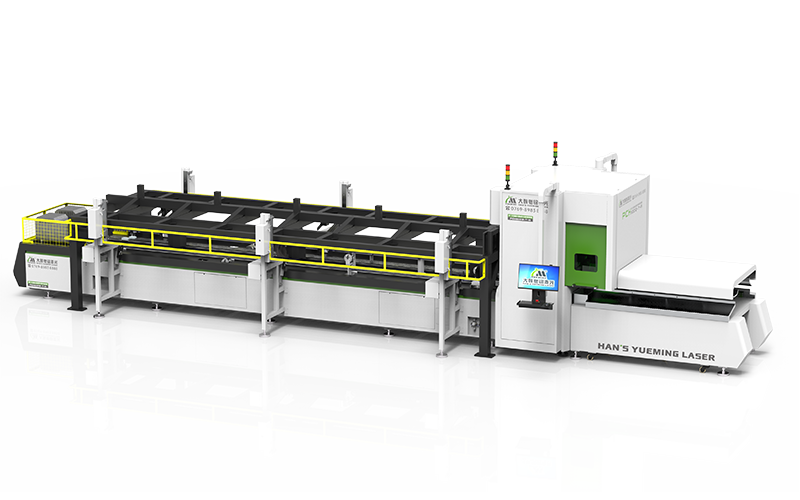

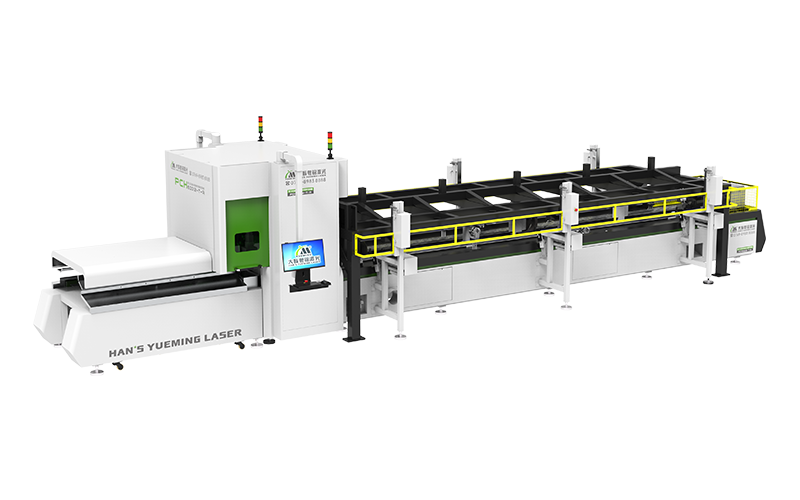

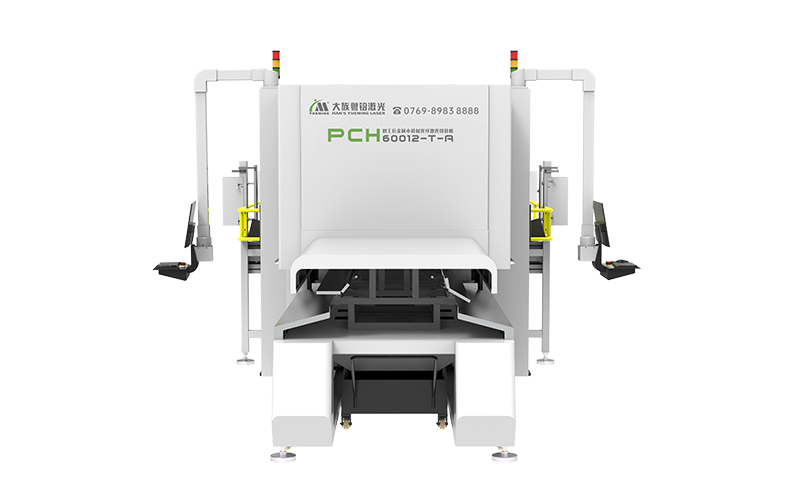

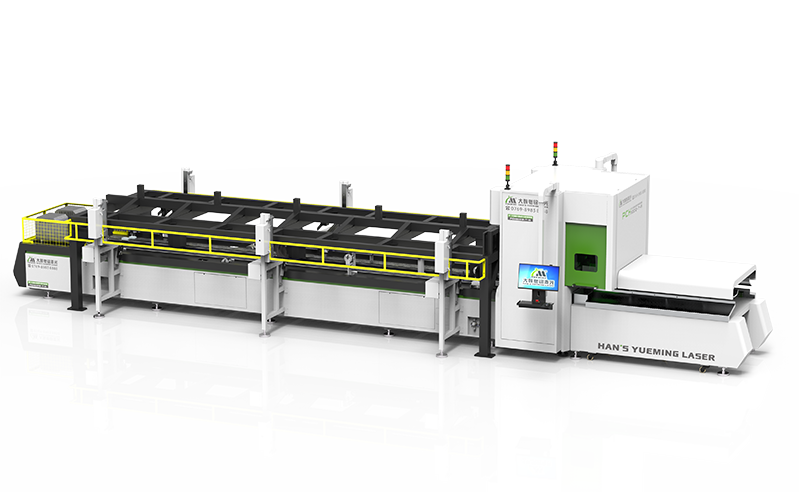

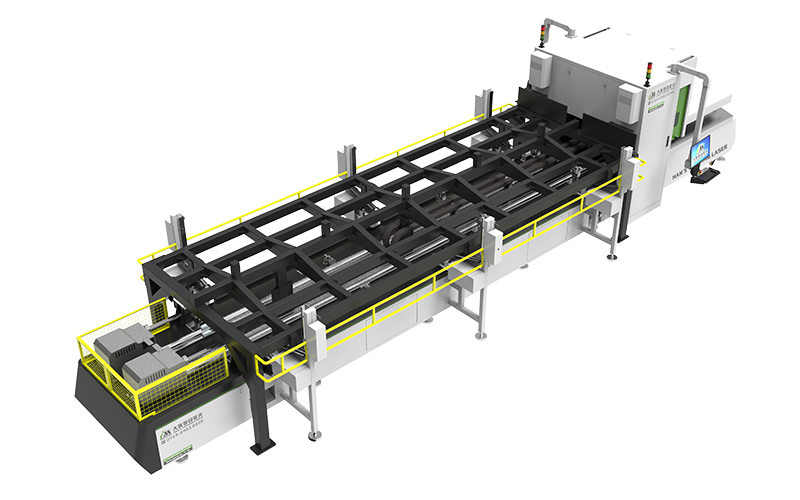

Model

2 in 1 Tube Fiber Laser Cutter for Small Tube

Introduction

Zero tailing tube cutting machine adopt zero waste chuck design scheme, save the waste of pipe; Top-mounted warehouse,50% floor area saved; Two station automatic feeding at the same time,Auto-adjusting four-jaw roller chuck; · Efficiency increased by 81% ,The floor area is reduced by 23%; Automatic tube loading mechanism, Two stations can be independently and automatically loading tube; Automatic tube clamping and centering no need to manually adjust the clamping position; Automatic and convenient material receiving design; One-person operate multi- machine.

Inquiry