Model

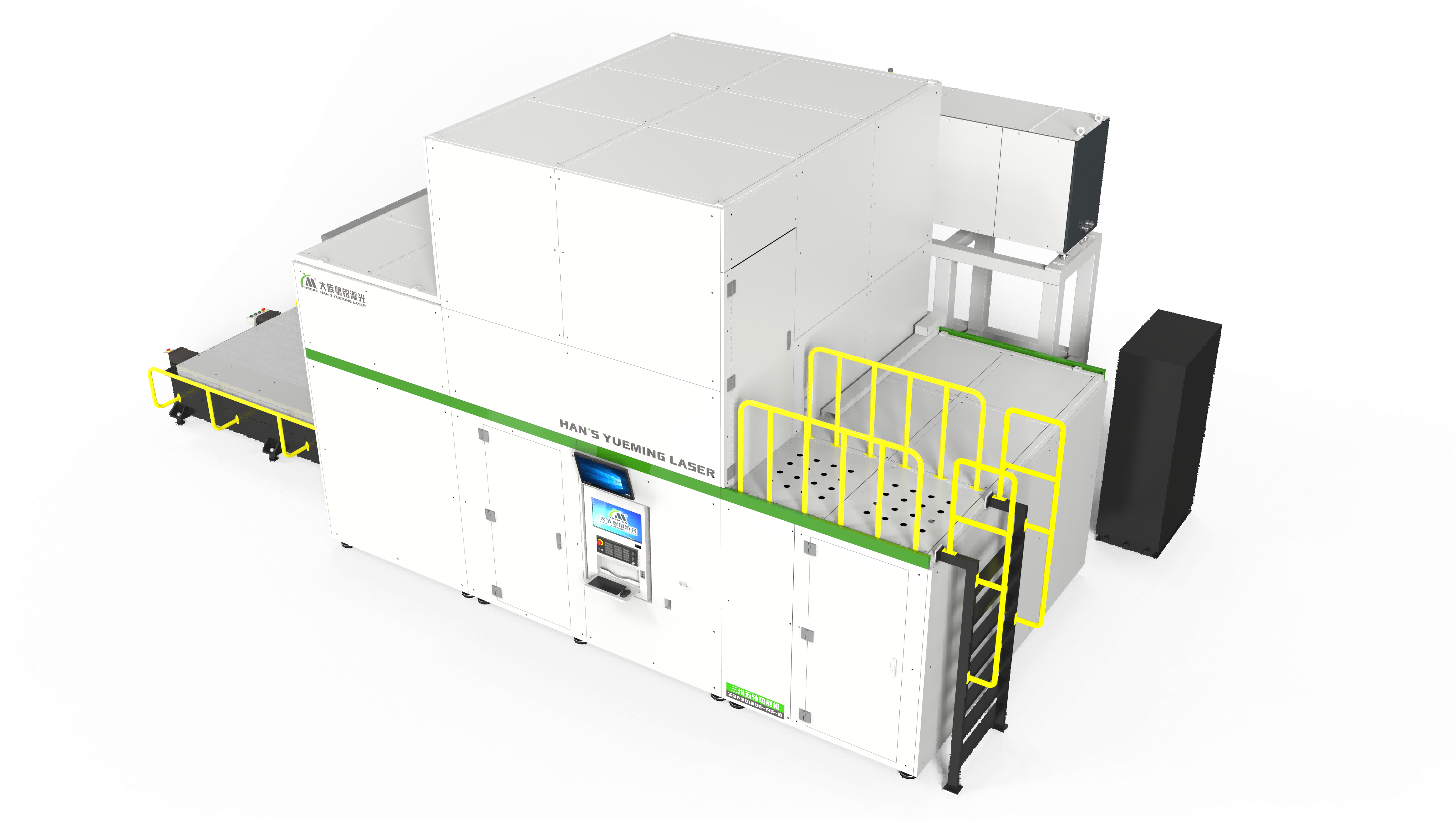

High-Precision 3D 5-Axis CO2 Laser Cutting Machine-SGF301805-A5-B

Introduction

Reinforced welding bed, fine milled by large gantry, with annealing treatment to eliminate the stress, ensuring the long-term stable running; Self-developed BC-axis cutting head, with slender nozzle and anti-collision design, enables C-axis rotate n*360°, and B-axis swing 130°; Imported CO2 laser generator, stable output and performance, high cutting precision, smooth and fine cutting edge; High-precision transmission system, rack + lead screw structure, gantry+ fixed beam design, and Y direction slide;

Inquiry