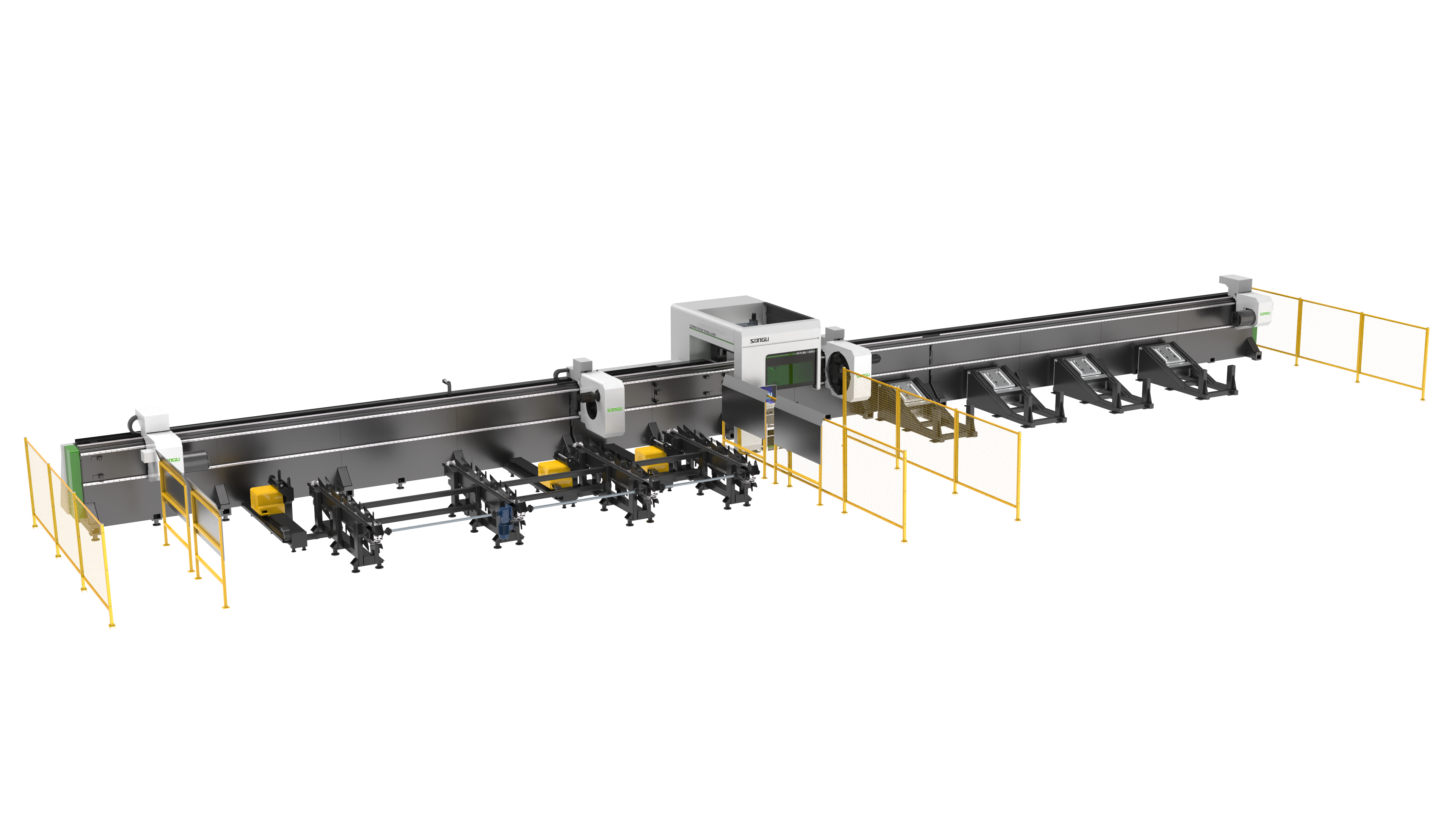

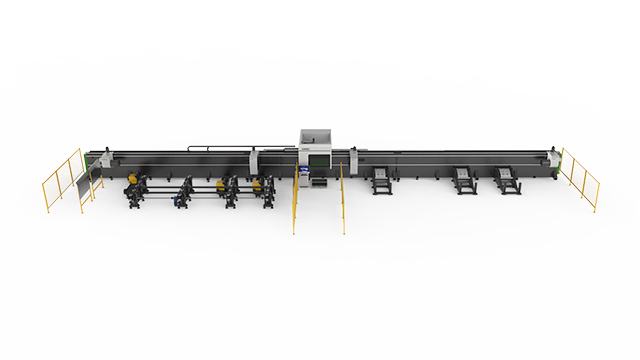

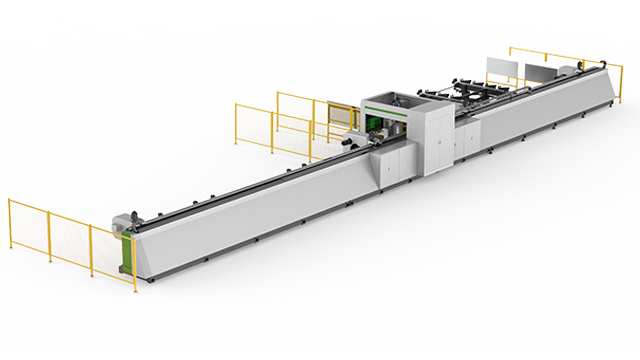

Model

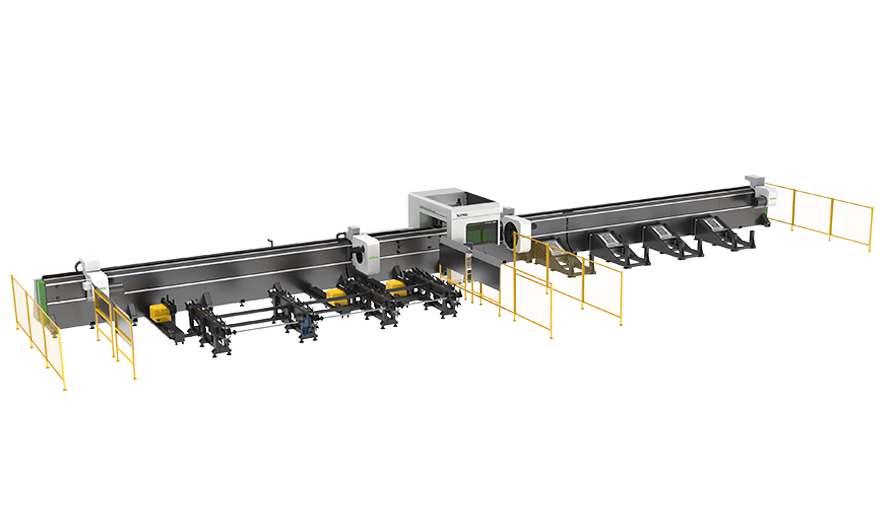

4-Chuck Tube Laser Cutter HyTube12052-D

Introduction

HyTube12052-D laser pipe cutting machine is a professional heavy-duty pipe processing 4-chuck laser pipe cutting machine tailor-made for steel structures, oil pipelines, construction machinery, and other industries; the equipment can be equipped with automatic upper and lower Material system scheme so that the overall processing efficiency of the equipment is more than doubled.

Inquiry