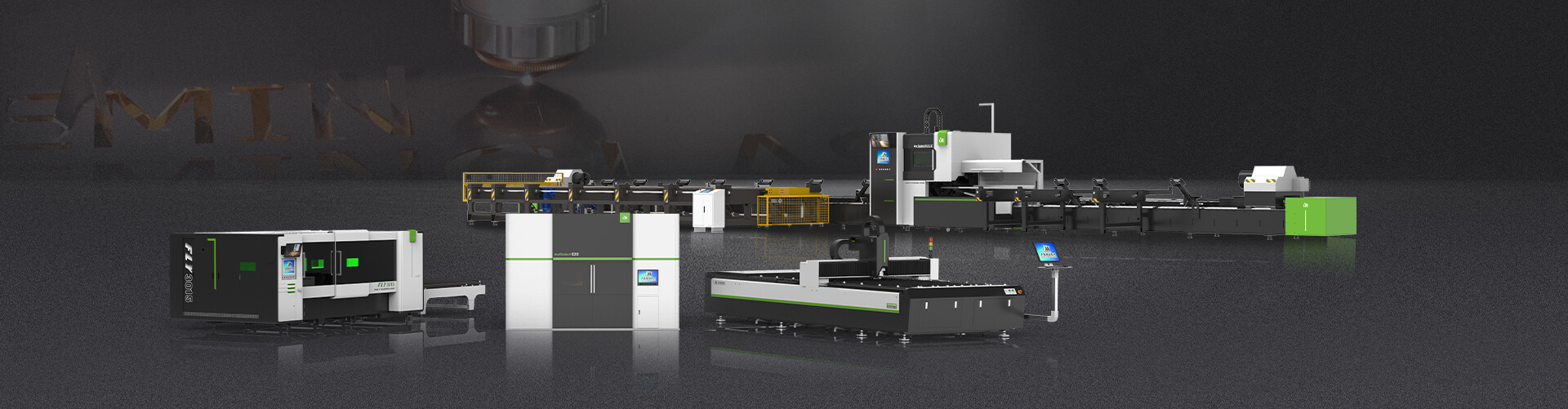

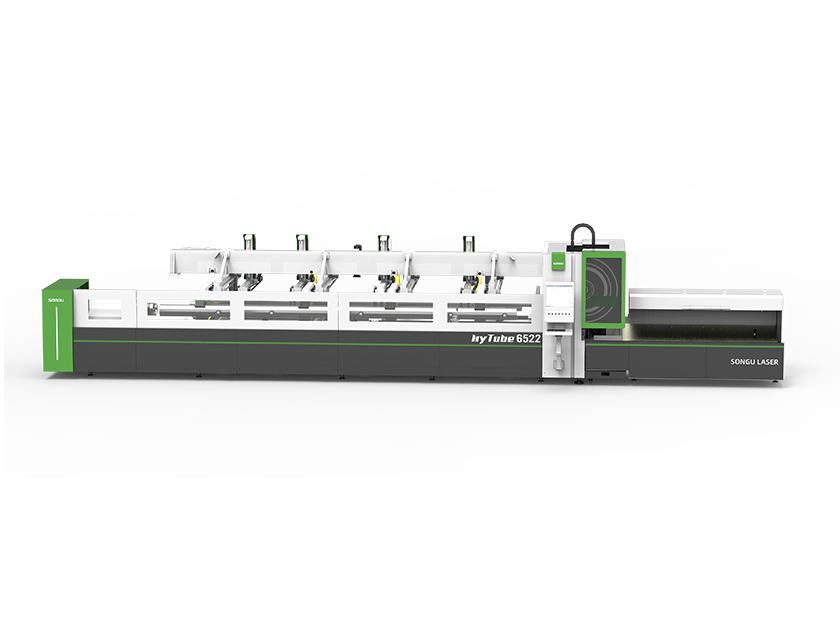

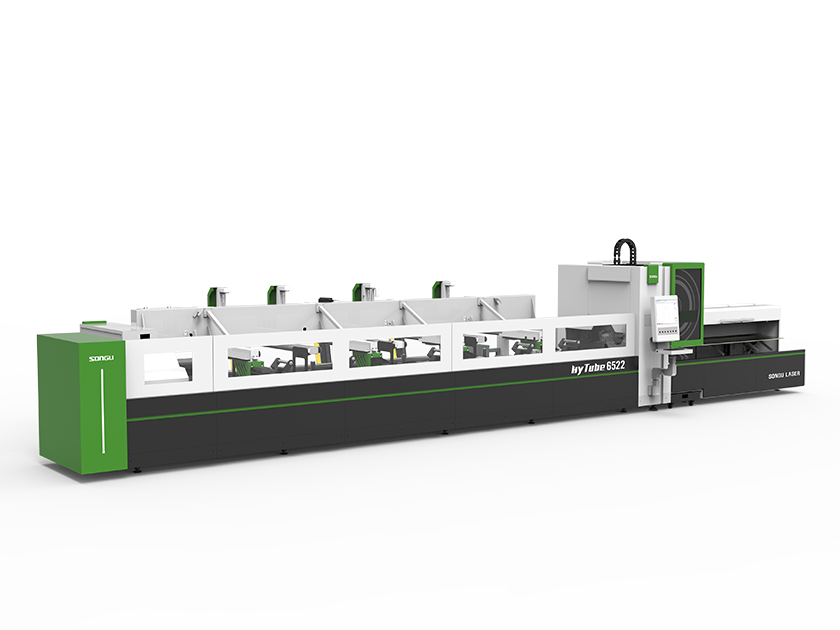

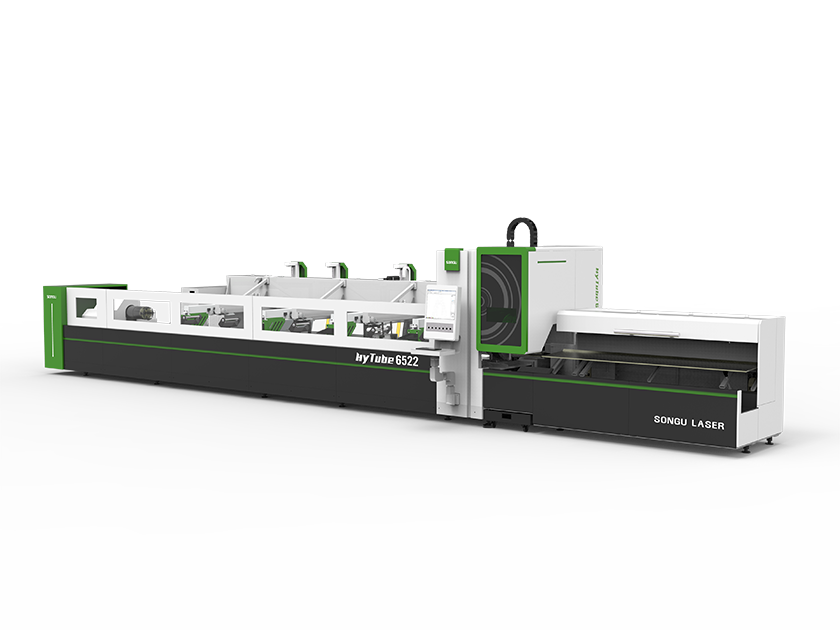

Model

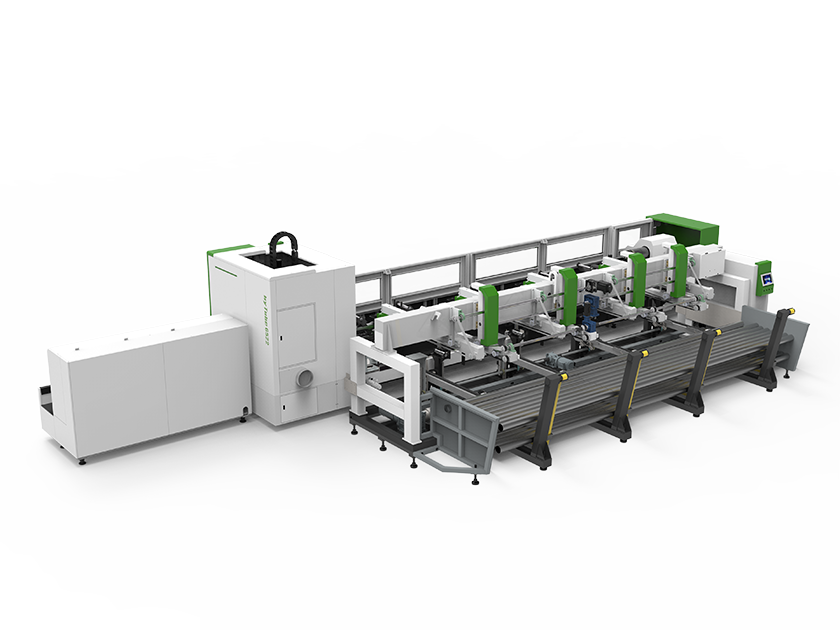

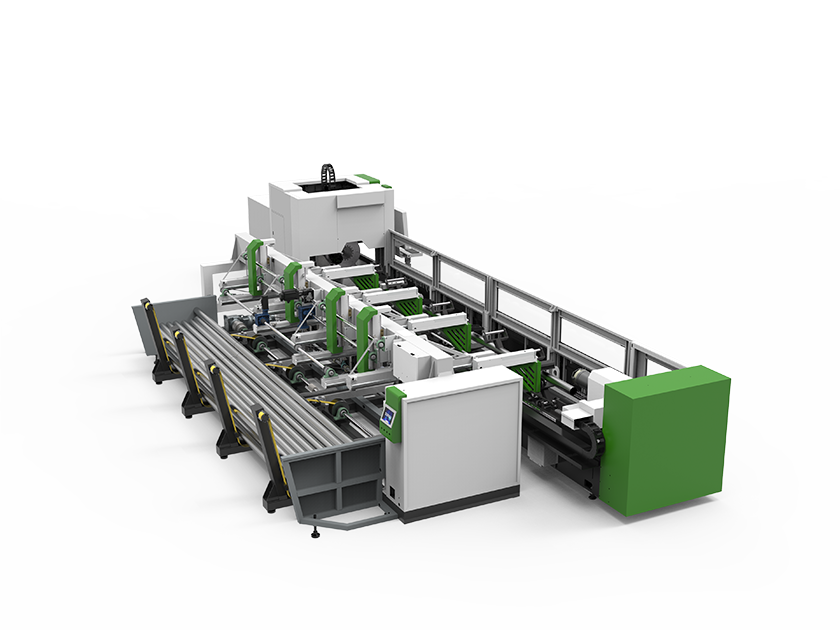

Tube Fiber Laser Cutting Machine Hytube6522

Introduction

FRIENDESS FSCUT3000S numerical control system based on Windows system, special platform of laser tube cutter, integrated with special function module of laser cutting control, powerful function, friendly interface, simple operation; The linear positioning speed can reach 100m/min, and the rotary positioning speed can reach 120m/min; Automatic bundle feeding function (optional) to reduce the number of operators and improve the processing efficiency.

Inquiry