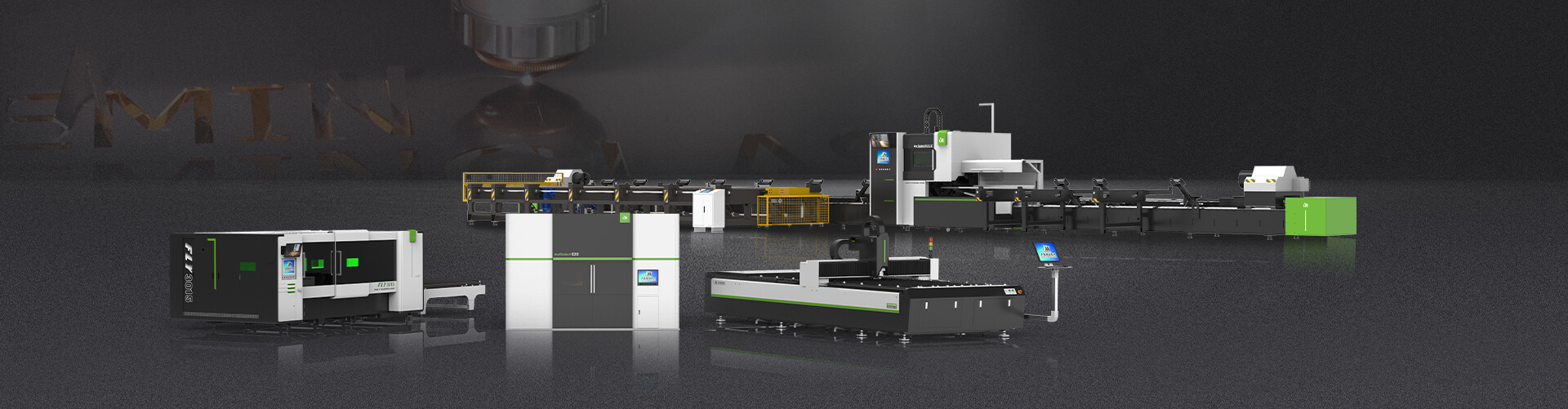

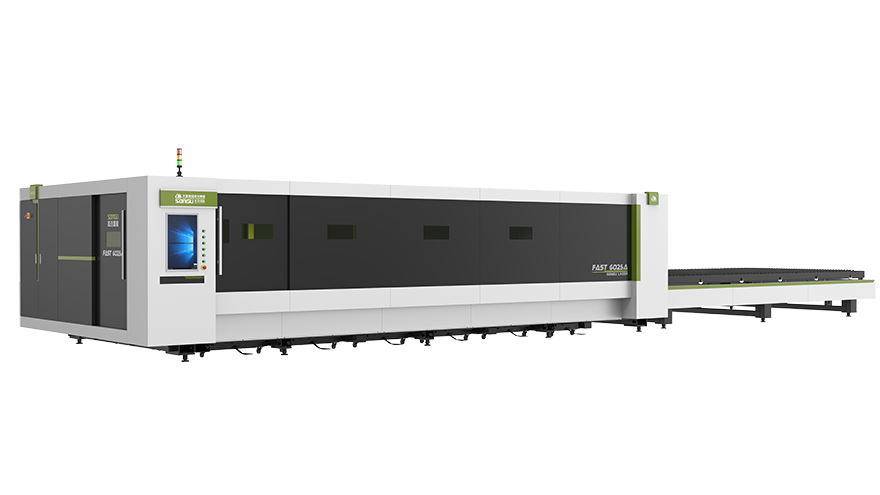

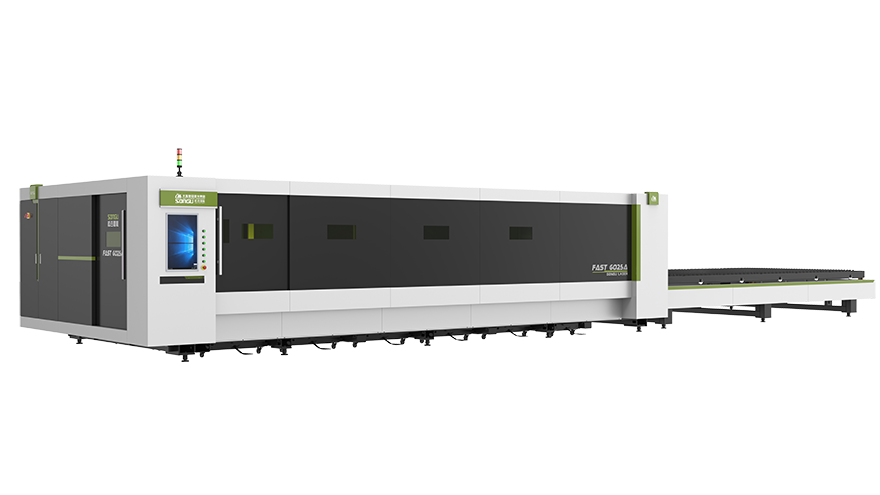

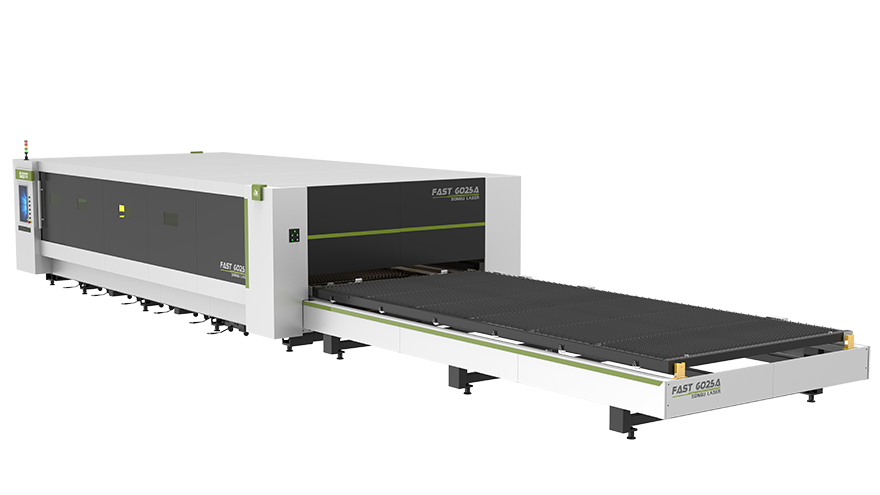

Model

FAST Series Fiber Laser Cutter

Introduction

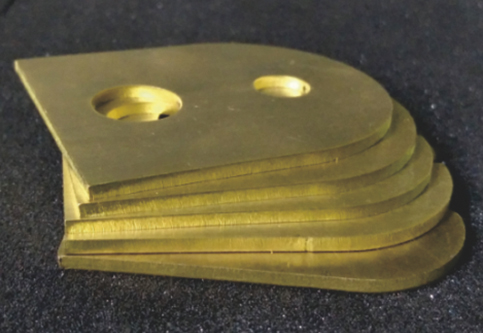

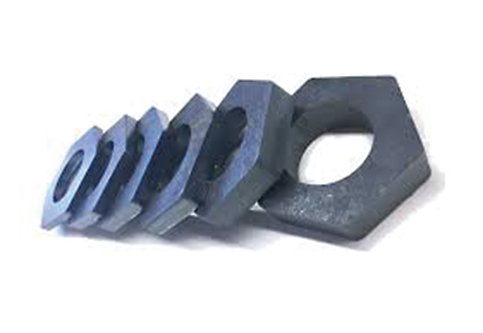

Autofocus laser head realizes 80% less time required for piercing than normal head, which is especially suitable for thick metal sheet and highly reflective materials; Applying High-quality laser achieves higher than 30% photoelectric conversion efficiency, and the machine will blow air while cutting, which can greatly lower the cost and improve the efficiency;Variable functions available, such as scanning cutting, blasting perforation, automatic edge finding and etc.

Inquiry