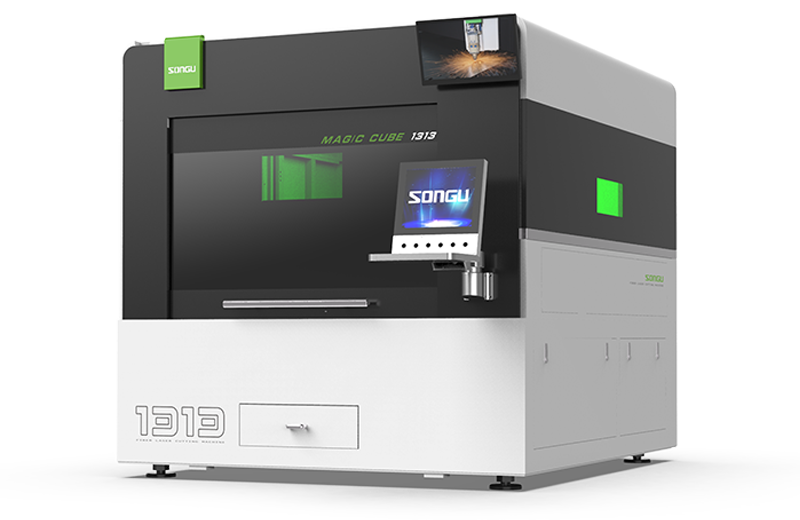

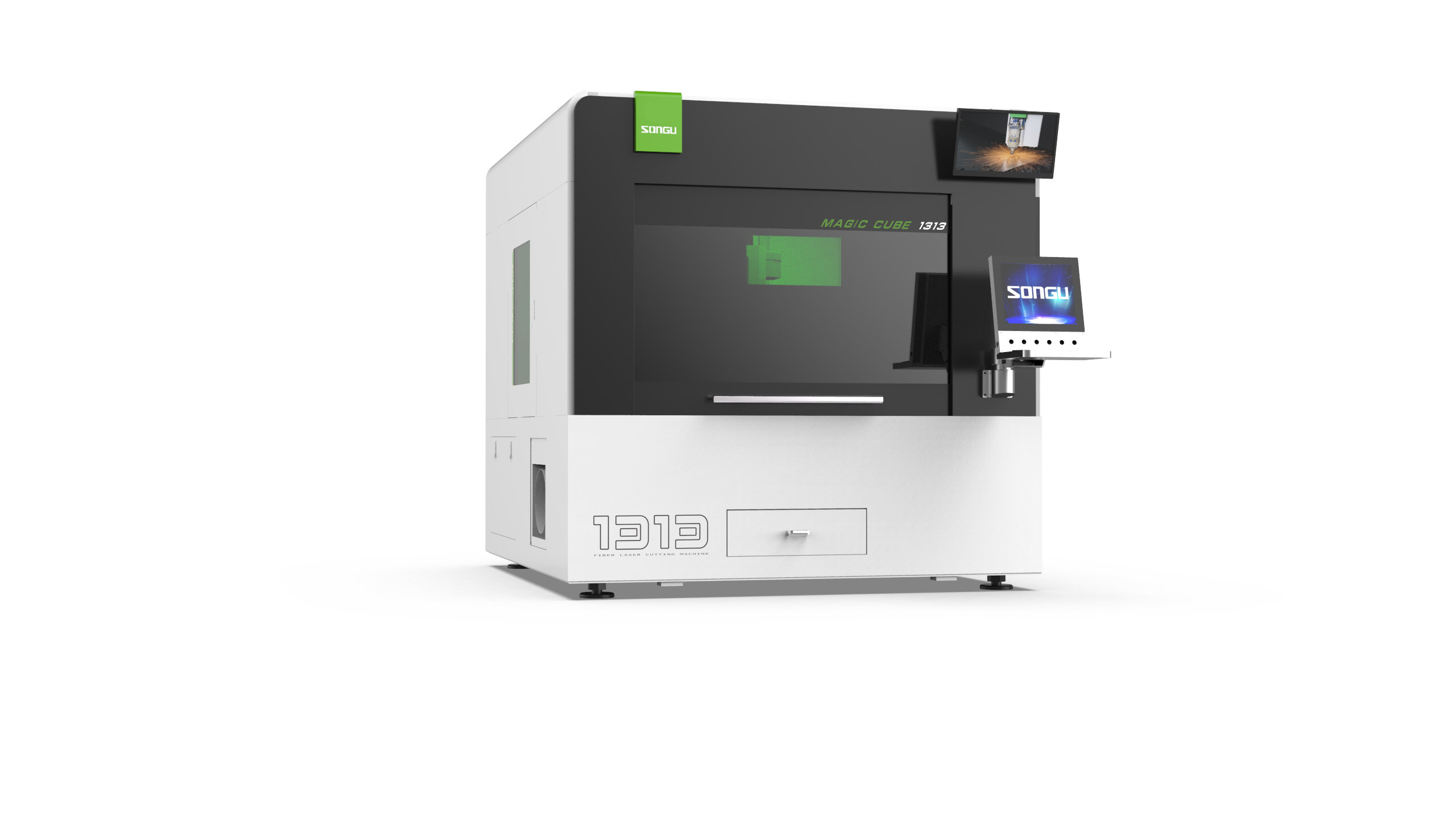

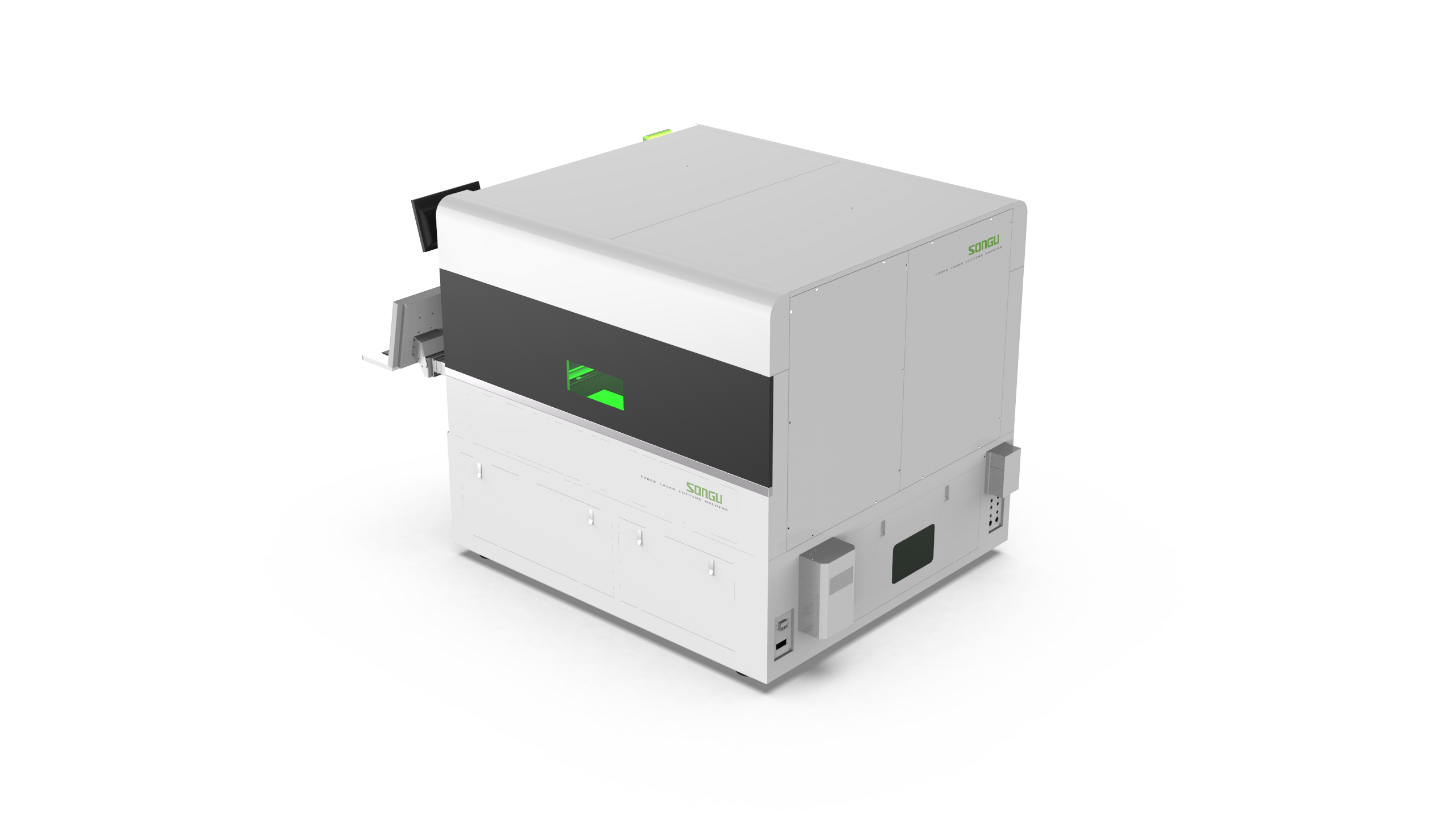

Model

Compact Fiber Laser Metal Sheet Cutting Machine Smart Cube 1313

Introduction

The light source uses Germany IPG laser, with high photoelectric conversion efficiency and low power loss; multi-modular design ensures uninterrupted work; laser response speed is fast and the effect is good; small size, less land occupation, saving space; Adopt gantry double-sided drive device, imported servo motor, equipped with high-precision reducer and rack and pinion, with high transmission dynamic efficiency and good stability; Automatic parameter selection, embedded design of all cutting parameters, automatic system setting , less manual intervention, simple operation; Automatic lubricating device, set working time and guide rail travel distance, automatic oil lubrication guide rail, long service life; Equipped with a "dual temperature and dual control" patented water chiller, it not only ensures the cooling equivalent of the equipment, but also maximizes the save energy and electricity to the maximum, and further reduce customer operating costs.

Inquiry

.png)

.png)

.png)