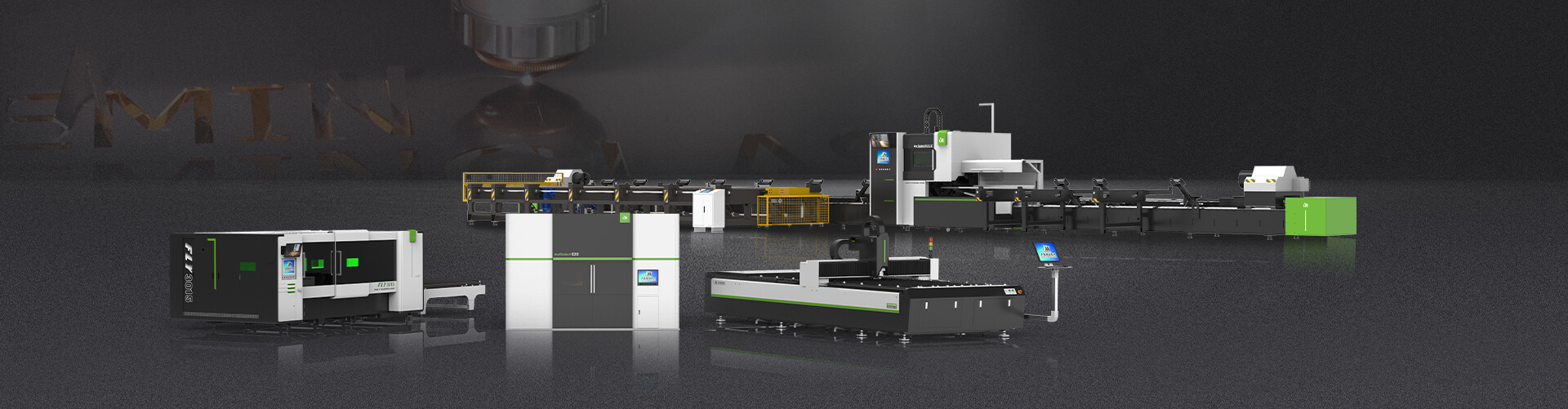

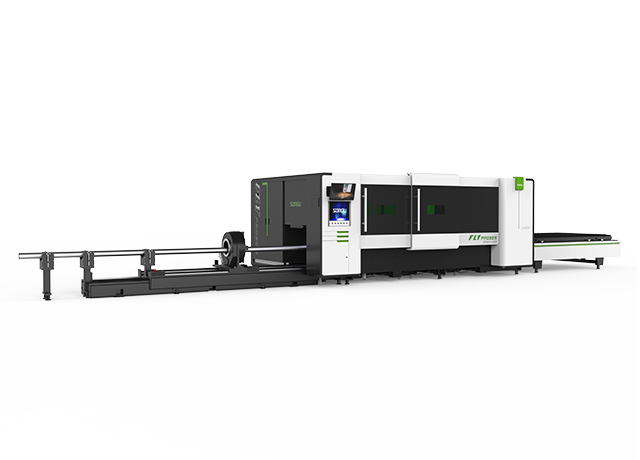

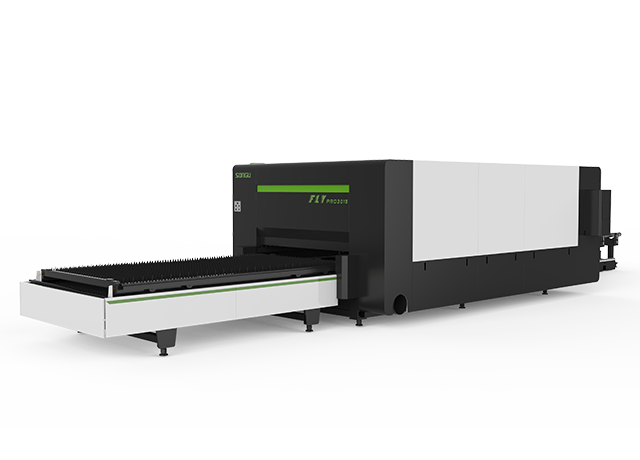

Model

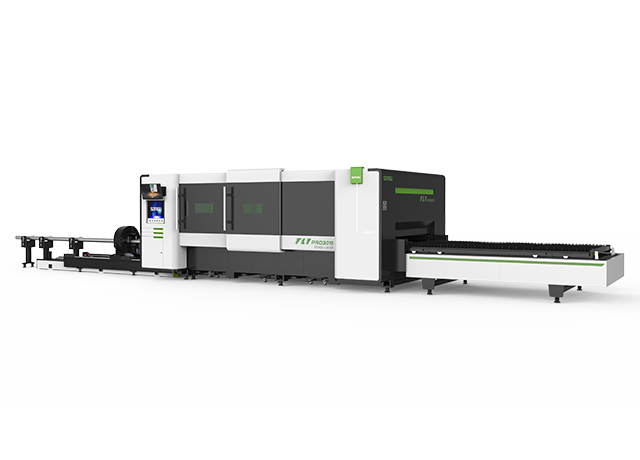

Fiber Laser Cutting Machine FLY Pro 3015

Introduction

Enclosed protection cover with safety interlock design,simple for operation; Pipe cutting is sealed inside of the machine protection housing, reduce accidental injury; Optional different types of jaws can realize the cutting processing of different profiles,such as: angle steel, channel steel, I-beam; Adopts gantry structure,guarantee the machine tool long term accuracy and stability; Equipped with a special workbench for pipe cutting to assist the processing and blanking of long pipe workpieces; Optional laser pipe cutting machine dedicated plat-form,the plate and tube can be switched at any time,front butt,and the side operation is close; Driven by high-precision servo motor, equipped with high-precision trans-mission mechanism, high installation accuracy, large transmission torque,small transmission error, and good dynamic characteristics; The pipe cutting mechanism feeds 3 meter at a time. After the cutting is completed, it is fed and processed one by one, which can complete the cutting process of raw material pipes of more than 6 meters.

Inquiry