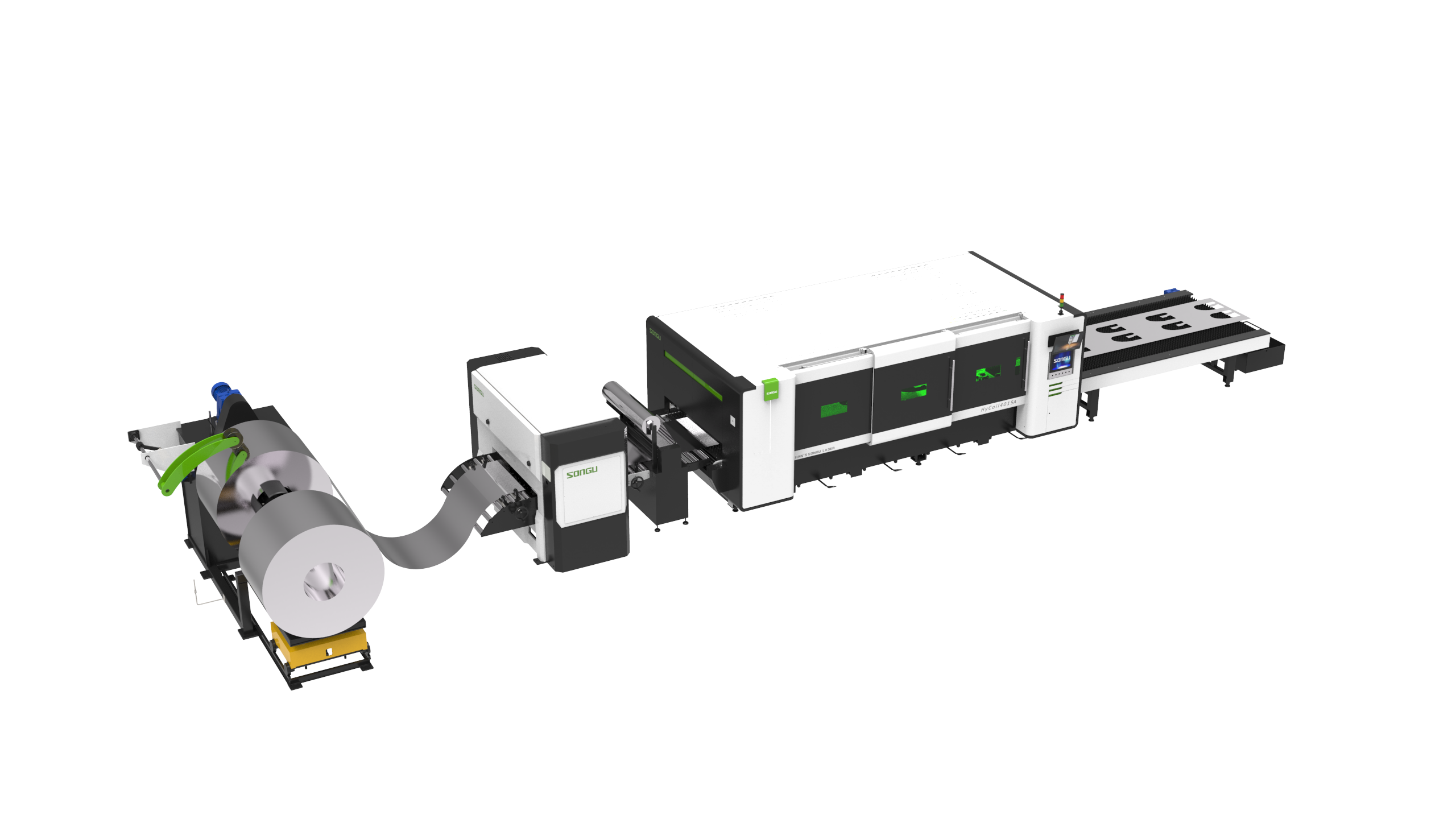

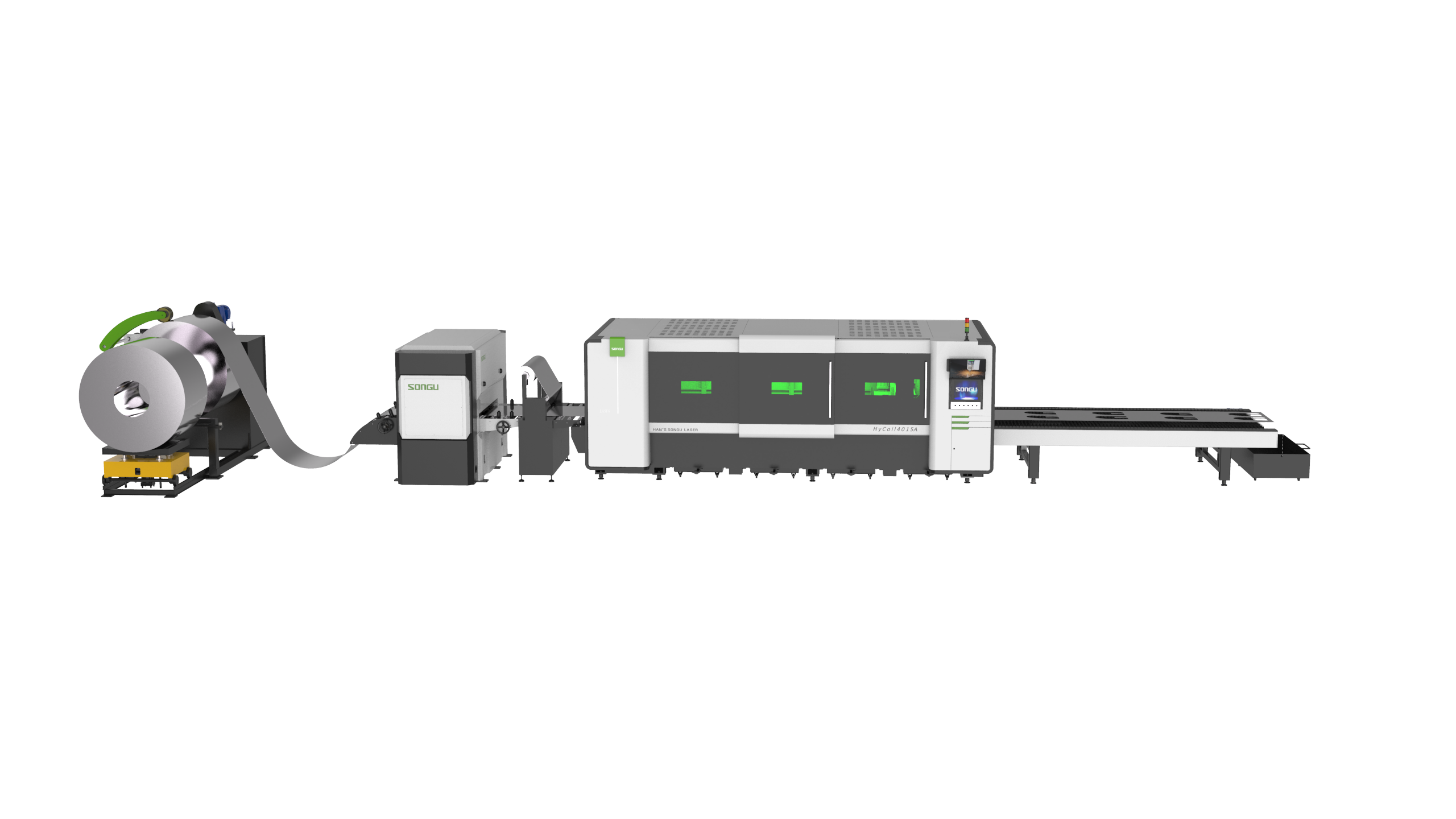

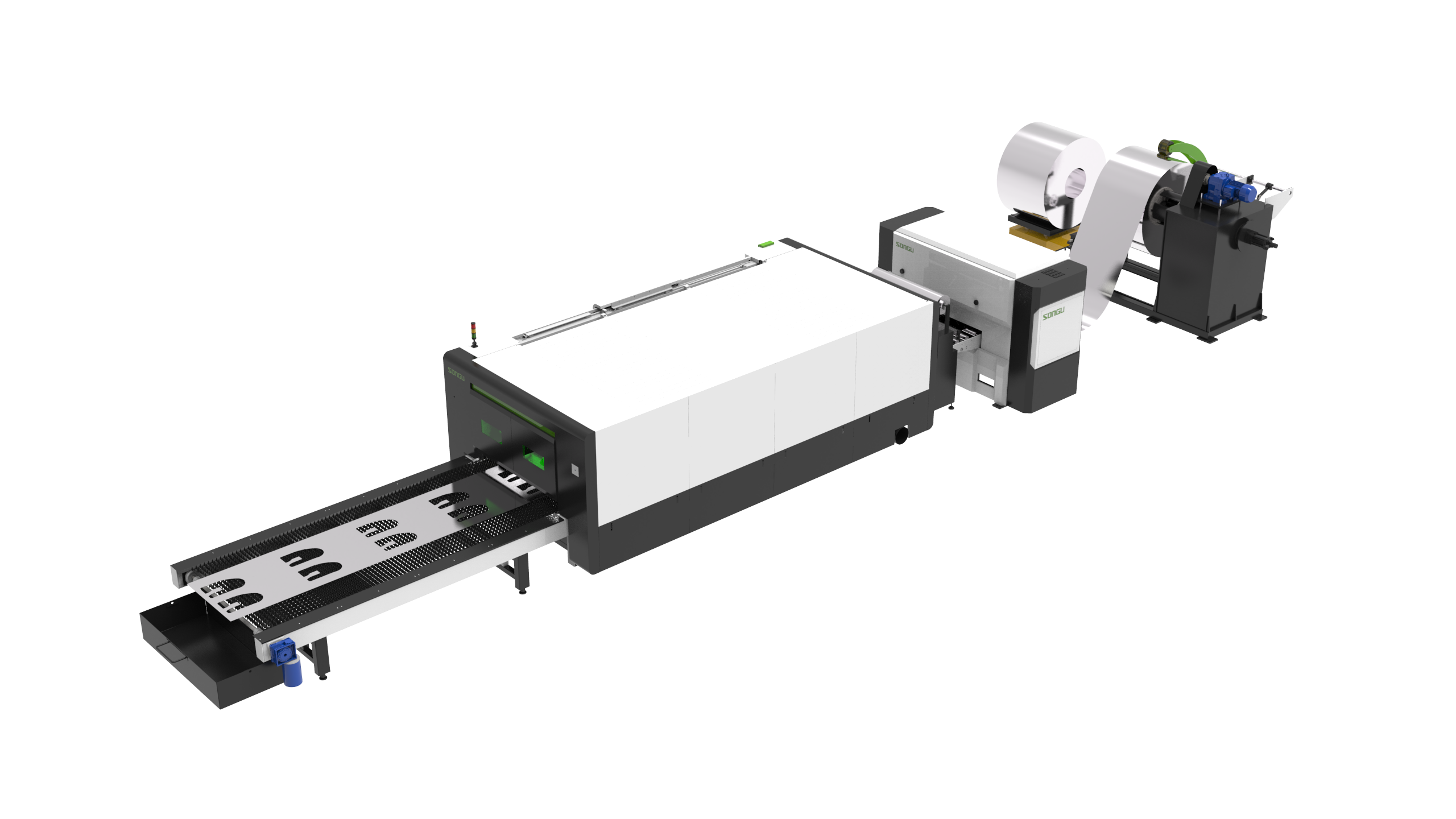

Model

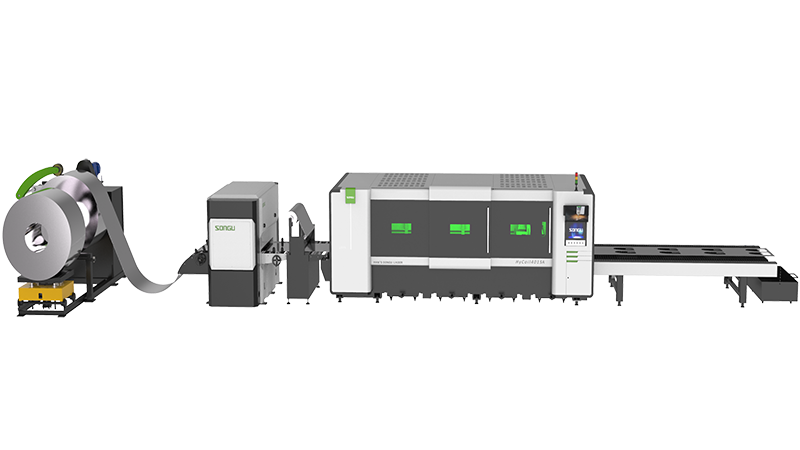

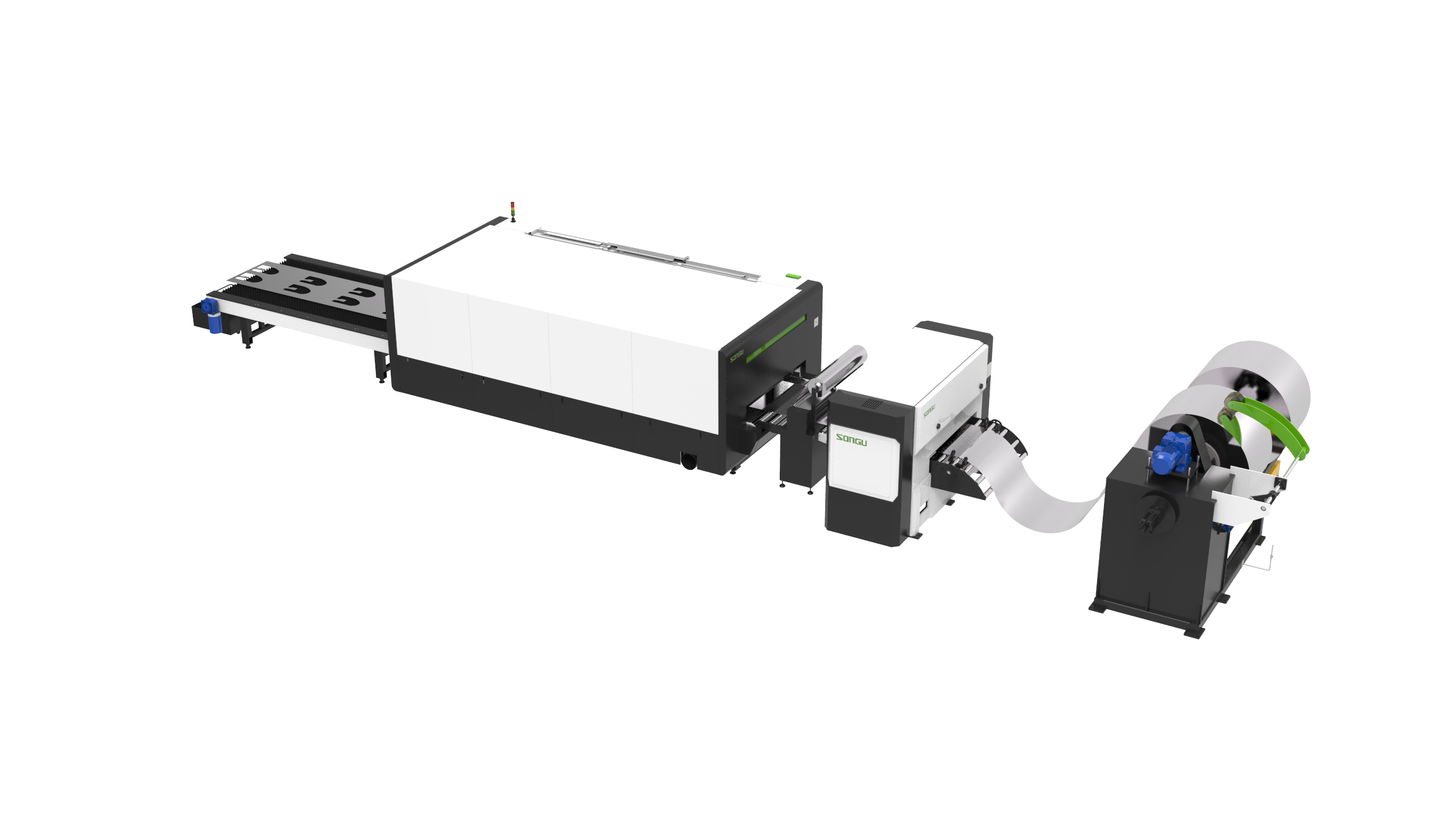

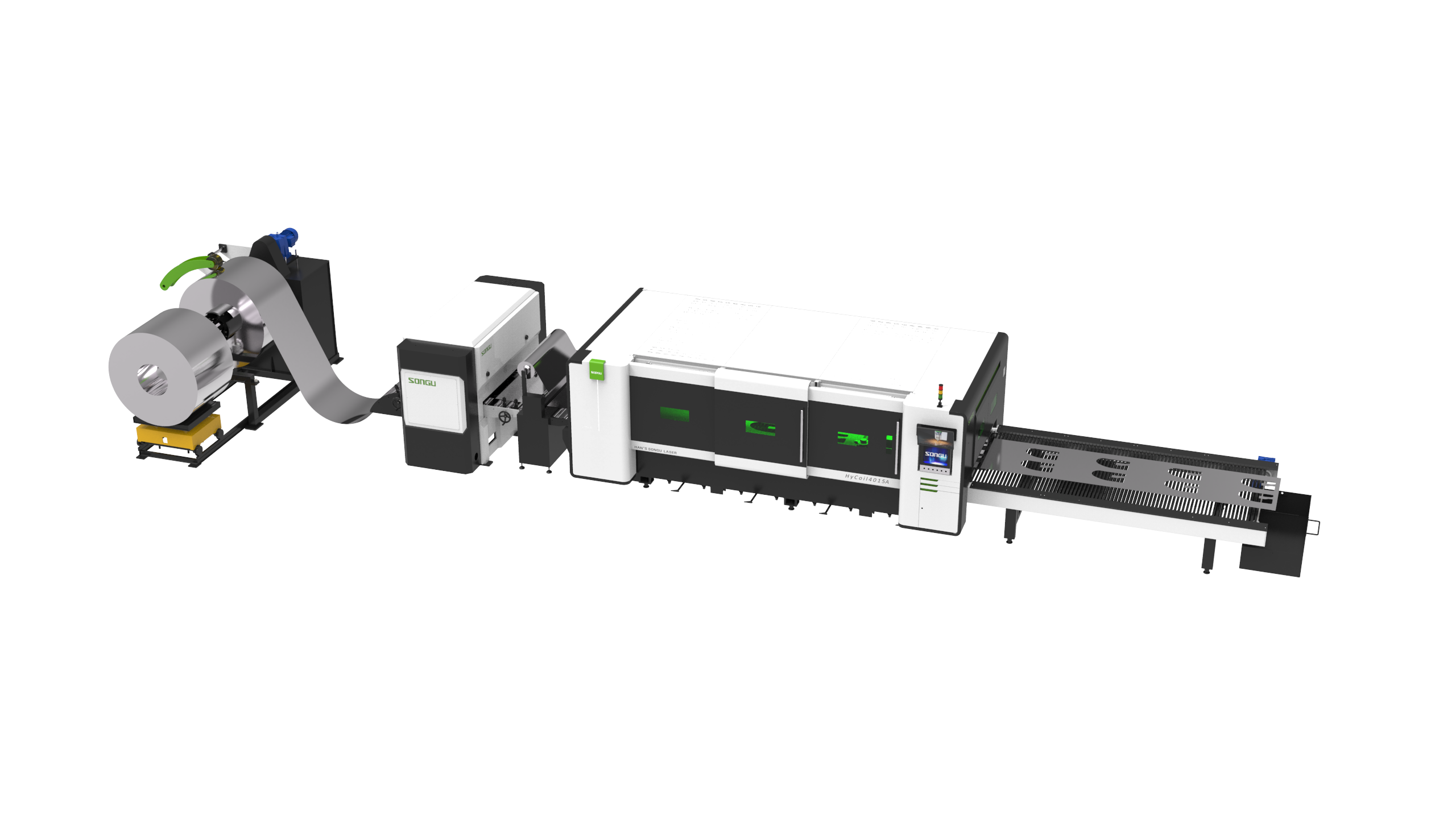

Hy4015-Coil coil laser blanking line

Introduction

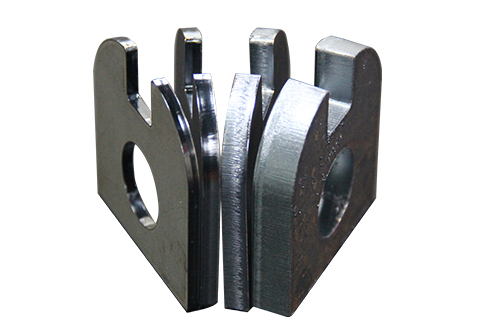

It can cut carbon steel plate, stainless steel plate, aluminum plate, especially ultra-high-strength steel plate which is very difficult to stamp with a punch press;The machine adopts high-precision leveling machine, high-precision feeding and cutting system, advanced automatic palletizing system, etc., which can adapt to the production of blank parts of various metal materials;

Inquiry