Model

Mach4020-A Fiber Laser Cutting Machine

Introduction

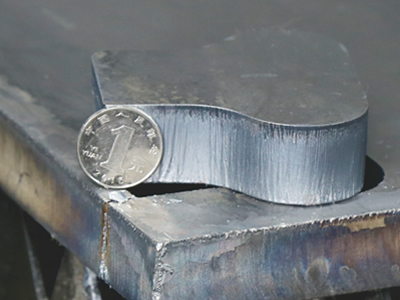

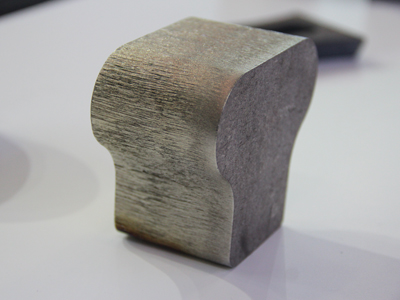

Developed variable frequency cutting zoom perforation technology ensures high-efficiency and high-quality processing of plates of different thicknesses and materials. All process parameters can be fully digitally controlled, which greatly reduces manual intervention and is intelligent and simple;Hydraulic lifting platform, stable and efficient cutting; The key components are all German accessories, high-end configuration, good stability and durability;

Inquiry